Machine Safety Project

Design a comprehensive safety package to guard against possible personnel injury……

Customer had Rockwell Automation personnel do a walk through and provide customer with recommendations on where, in their opinion, hazardous areas on the machine might exist. The customer turned over the report to us to use as a guide to produce a comprehensive guarding package.

The final product…..

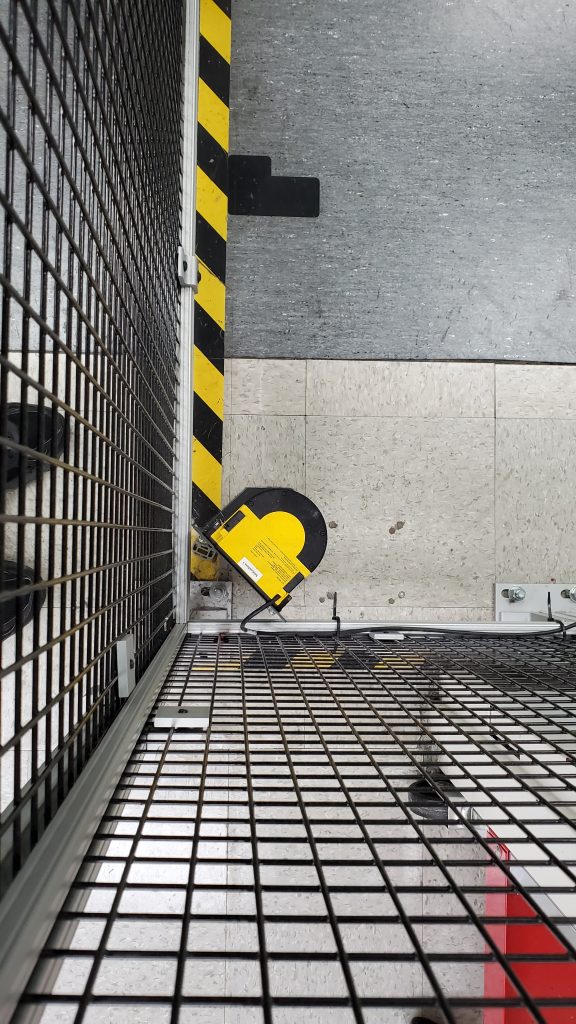

Physical Gating was placed around each machine with entry to the machine area through a sliding gate that remained lock by a Rockwell Guardmaster RFID controlled safety lock that can only open when certain criteria are met.

Perimeter Guarding was placed at each corner using Keyence Laser Sensors (SZ-V Model).

Enclosure with the Allen Bradley Panelview 800 HMI is the safety panel that was added. The Safety Panel houses the Rockwell Automation Guardmaster Safety Programmable Relay (Model 440C-CR30). The Safety Relay is setup to monitor all the safety equipment around the machine such as the OSSD signals from the Safety Gate Locking Switch, the Safety Rated Ross Air valve, the Safety rated E-Stop pushbuttons, and the Keyence Safety Lasers.

As can be seen from the picture, when the machine is fully safe and operational the HMI displays all indicators in green. When Indicators are red (as seen on the panel below) the machine is rendered inoperable.