Commercial Airline Oxygen Mask Release Switch Testing…..

Customer wanted to have a tester built that could accommodate the testing of the Oxygen Mask release switches on commercial aircraft. Customer was doing switch testing 1 at a time. This was a very time-consuming operation as well as subject to operator error.

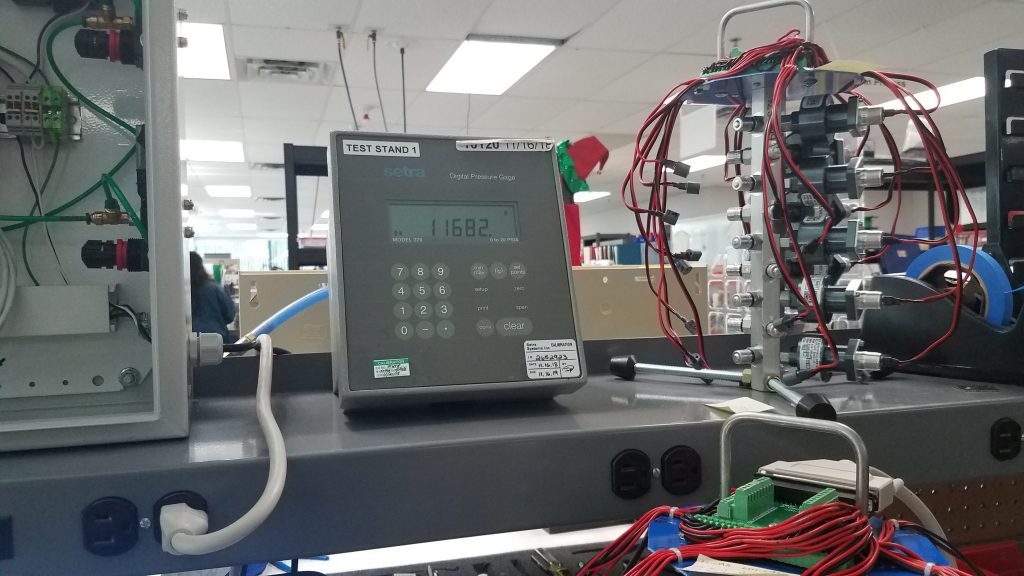

The client’s mechanical engineers designed the switch testing fixtures to enable testing of 20 switches at the same time. An altitude simulator (see below) was used to provide altitude information in the form of a vacuum (supplied through a vacuum pump assembly) to the switch testing fixtures. The switches were electrically connected to a computerized control system that we designed.

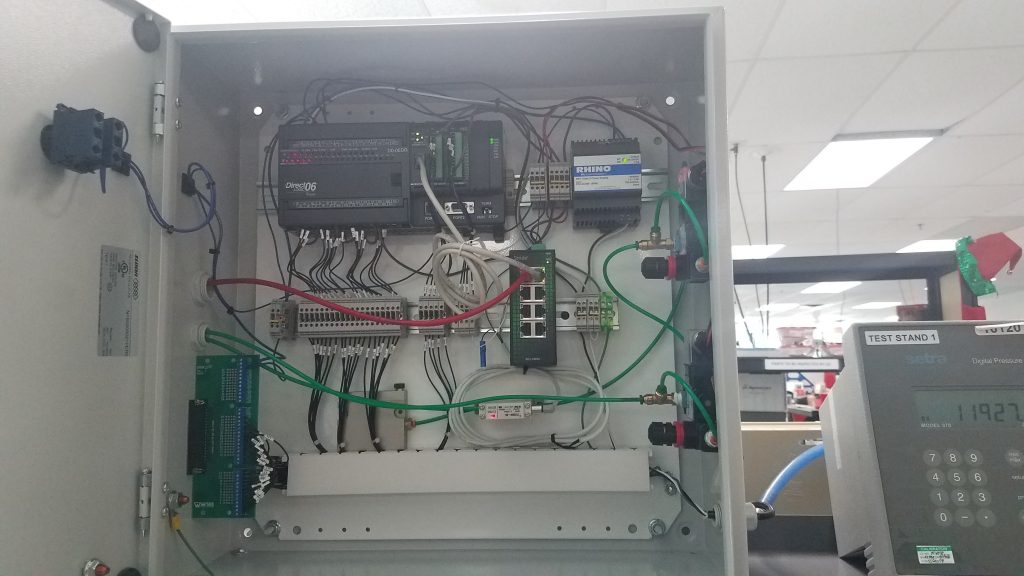

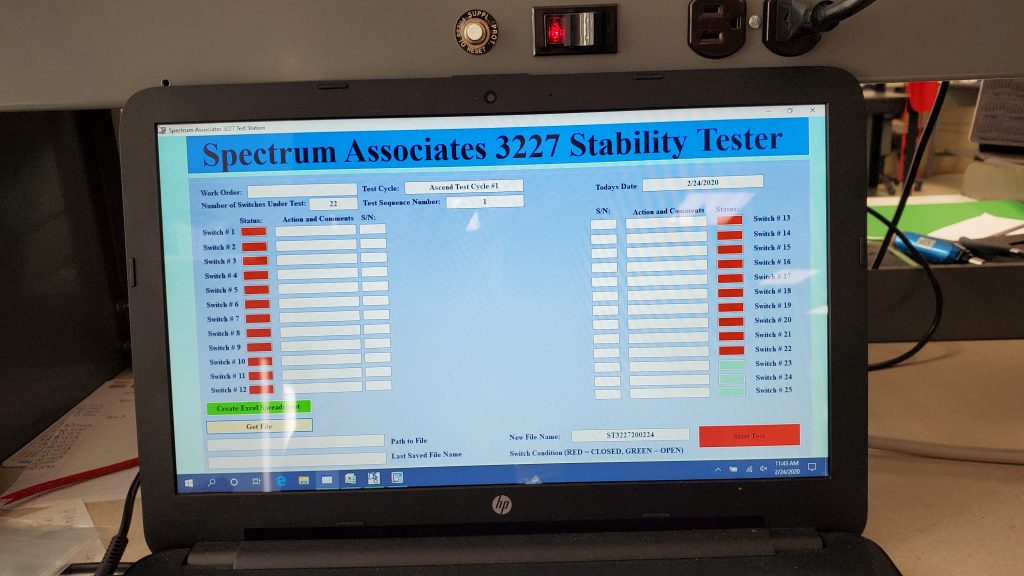

As can be seen from the above picture the control side consisted of an Automation Direct PLC (Model DL-06), connected via ethernet connection to the PC. The Altitude Simulator communicated to the PC via RS-232 ASCII. Switch closure/opening was monitored by the PLC. At the exact movement of a change in switch position an altitude reading was obtained and recorded in an Excel Spreadsheet.

The Tester PC monitored and recorded the switch operation. After receiving a signal from the PLC as to which switch had operated the PC immediately queried the Altitude Simulator for the present altitude. The reading was recorded in the appropriate Excel cell.